Redesigning Imported Chocolate Tin to a Cartonboard Alternative – Case Study

Cost savings in manufacture & shipping and not having to ship empty space

We were asked by one of our customers to design an alternative option for their Christmas chocolates tin which they had manufactured in China. When shipping costs alone increased by about 15x in 2021 it made the product unsustainable to import, especially given the fact that they were effectively shipping a lot of empty space inside the tins.

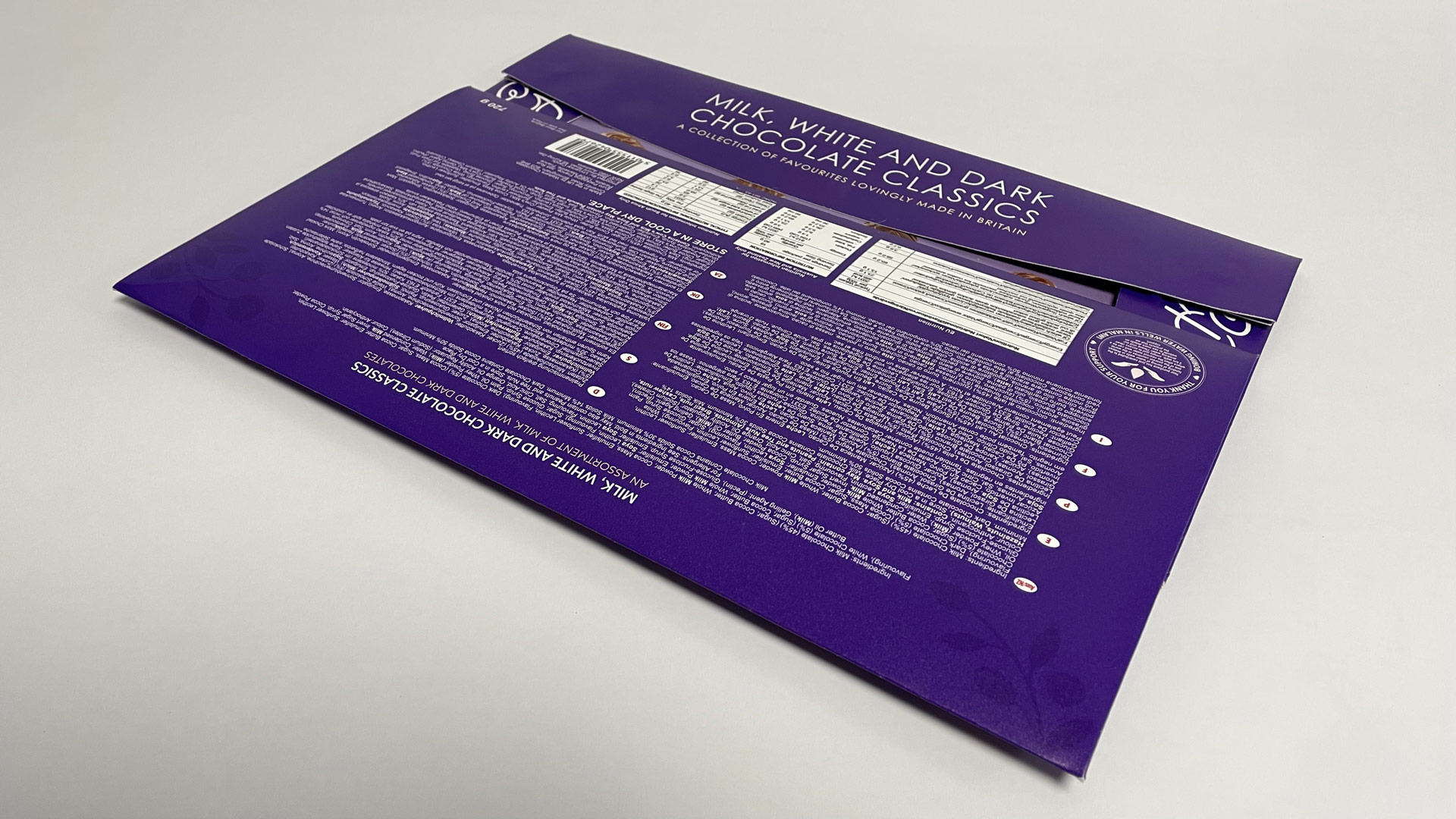

We worked with them to design a 6 corner glued 700 micron folding box board alternative, this has all the space for artwork, keeps the products on display when opened and can be opened and closed with a hinged lid. There was the option for internal print on the lid for the chocolate selection as well as foiling on the outside for premium options.

The box holds three levels of chocolates in vac formed fitments weighing 720g, so this is at the larger end of the gifting market. When glued they are packed flat, compared to shipping empty tins which cannot be stacked or reduced in size for shipping, this therefore reduces the amount of boxes/pallets needed for shipping and the amount of space needed for storage.